THE SCIENCE

THE SCIENCE

WE KILL GERMS.

EVERYWHERE.

Germ Free is an alternative cleaning and disinfection company specializing in Electrochemically Activated (ECA) fluids. Using all natural, EPA-registered formulas, we help eliminate cross contamination and hospital acquired infections.

Certified safe by the Environmental Protection Agency, our disinfecting solutions safety clean and disinfect entire rooms — including floors, walls, drapes, mattresses, chairs, flat surfaces, shaded spots, and hard to reach areas. In the process, we effectively eradicate pathogens, viruses, algae and fungi because we can achieve a degree of disinfection that cannot be achieved with traditional cleaners.

WE KILL VIRUSES

EVERYWHERE, TOO.

Our Electrochemically Activated (ECA) fluids replace conventional chemicals and is proven effective on all viruses such as Methicillin-Resistant Staphylococcus Aureus (MRSA), Vancomycin-resistant Enterococcus (VRE), Multidrug-resistant gram-negative bacilli (MDR- GNB).

The system Germ Free Company uses continues to see unprecedented success in high traffic areas such as hospitals, hotels, municipal buildings, gyms, cruise lines, court houses, and hundreds of other facilities.

AN URGENT NEED

FOR GERM FREE

According to the CDC, at least two million people are infected by resistant bacteria and 23,000 die from the infections annually.1 Even more alarming, it’s estimated that by the year 2050, antimicrobial resistant pathogens are going to be the main cause of death, killing 10 million people annually.2 The only disease remotely close to that is cancer at 8.2 million annually. That’s why Jennifer created Germ Free Company’s breakthrough Infection Control System for Healthcare facilities, homes and businesses.

NATURE’S PERFECT

GERM KILLER

Powerful enough to kill E-coli, yet safe enough to spray in large areas using our Electrochemically Activated (ECA) fluids, our Infection Control System is considered nature’s perfect germ killer. It may sound like fantasy, but it’s actually chemistry.

Using our patented air-assisted electrostatic technology, we effectively weaponize two of the most natural and safe disinfectants found in nature: Hypochlorous Acid and Sodium Chloride. Combining these two solutions and electrochemically activating them gives us the potential of exceeding the disinfecting properties of bleach as much as 300 times. And that means we offer you the…

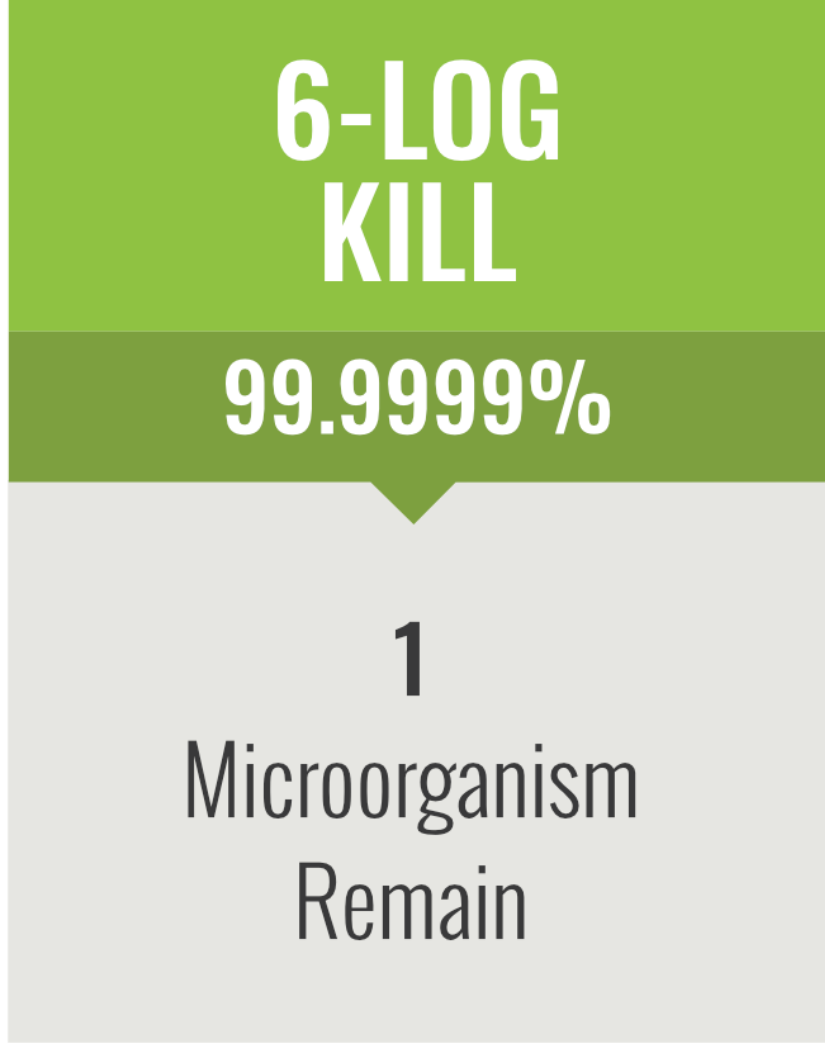

KILLING EFFICACY OF 6-LOG REDUCTION

Efficacy of a high-level disinfectant refers to its ability to kill bacteria. A 6-log kill rate is the highest validated efficacy on the market today, and represents a near-sterilization for the disinfected space. It’s the gold standard for whole room disinfection-and the only standard for Germ Free Company.

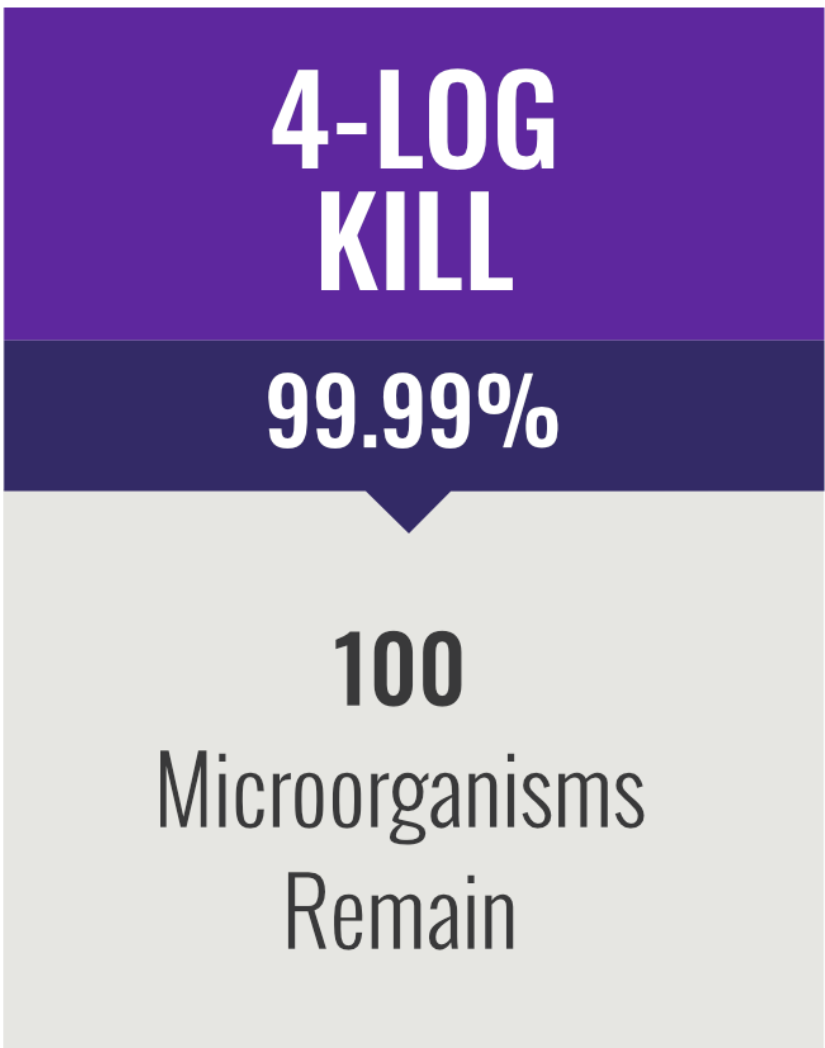

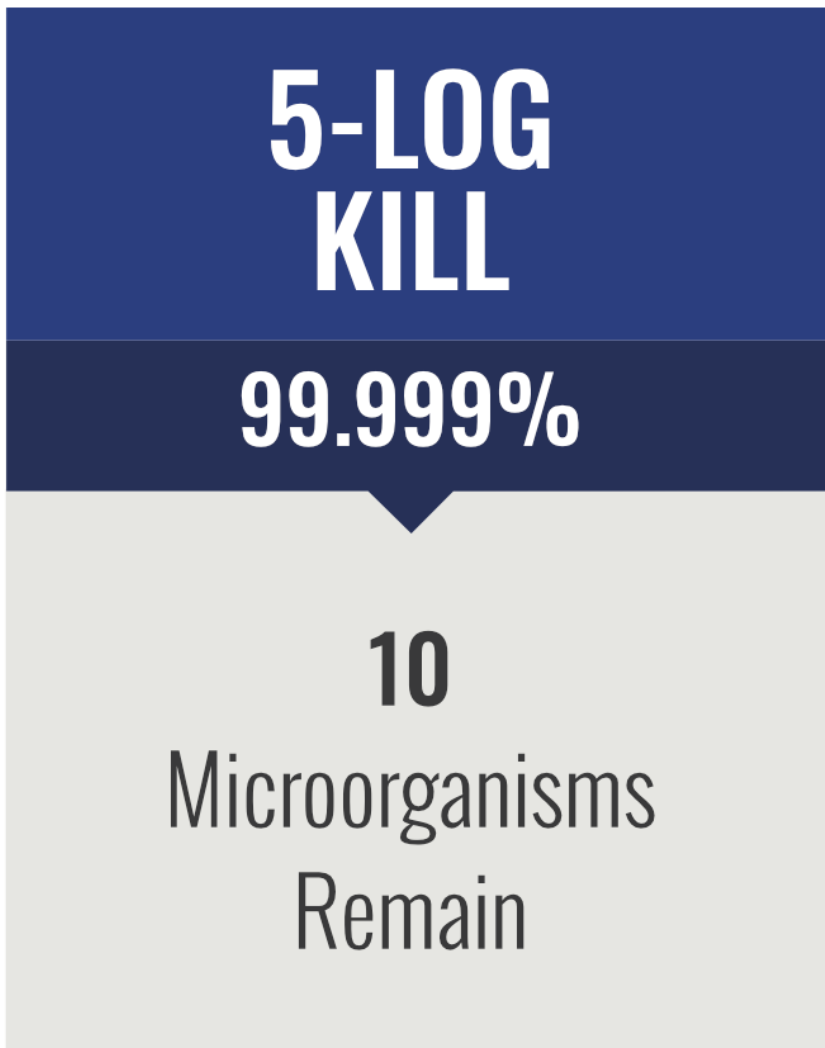

The scientific and medical industries measure the efficacy of a cleaning and disinfection solution using a logarithmic scale to show the relative number of microorganisms eliminated as a result of disinfection efforts. In the lab, scientists introduce 1,000,000 microorganisms to a test surface (per Federal standards) and use various chemicals to determine how effective they are at killing germs, bacteria and viruses.

- 1-Log Kill (90%) leaves 100,000 microorganisms

- 2-Log Kill (99%) leaves 10,000 microorganisms

- 3-Log Kill (99.9%) leaves 1,000 microorganisms — bleach and aerosol-type products

- 4-Log Kill (99.99%) leaves 100 microorganisms

- 5-Log Kill (99.999%) leaves 10 microorganisms

- 6–Log Kill (99.9999%) leaves 1 microorganism — Germ Free Company

WHOLE ROOM

DISINFECTION

Whole room disinfection is every hospital’s greatest goal. It’s also the greatest challenge. That’s because manual disinfection is well known to be the least effective coverage due to human error and hard-to-reach pathogens. Our electrostatic spraying system emits a mist so fine, the droplets actually reverse direction-making it a whole room capable disinfectant. This electro-mist moves upward against gravity to coat even the most hard to reach and hidden surfaces. Places like under bed rails, shadowed areas like corners and closets, surfaces out of the line of sight like the top of cabinets, and in between equipment or furniture. Remarkably, all this…

HELPS HOSPITALS

STAY EPA COMPLIANT

We all know the Occupational Safety and Health Administration (OSHA), as well as the National Institute for Occupational Safety and Health (NIOSH), insist on complying with the Environmental Protection Agency’s (EPA) mandate of choosing the least hazardous cleaning chemical that will accomplish the task at hand.

Now, with Germ Free Company’s Electrochemically Activated fluids that include Hypochlorous acid, becoming and staying EPA compliant is easier than ever. That’s because electrochemically generated NaOH (sodium hydroxide) and HOCI (Hypochlorous Acid) are without parallel as best practice cleaning and disinfecting solutions without harsh chemicals. And that’s why our Electrochemically Activated solutions…

OSHA

EPA

REPLACES 90% OF

OTHER CHEMICALS

As an all natural cleaning solution, Germ Free Company’s Infection Control System easily replaces conventional chemicals. In fact, we can replace at least 90% of all traditional chemical cleaners and disinfectants. The advantages are unparalleled, too. Take, for example, our solutions are biodegradable, non-toxic and leave no residues.

Please keep in mind you are not sacrificing efficacy, either. The truth is, you are probably increasing the germ killing efficacy tremendously. Our all natural, EPA approved products kill most food borne bacteria within five seconds. They are proven effective on all viruses and microbes such as Methicillin-Resistant Staphylococcus Aureus (MRSA), Vancomycin- resistant Enterococcus (VRE), Multidrug-resistant gram-negative bacilli (MDR-GNB), and many others in under 10 minutes. Plus, there’s one other advantage worth mentioning…

BETTER THAN

UV LIGHT DISINFECTION

If your hospital uses UV-C or PX-UV light products to disinfect rooms, you may be surprised—shocked, even—to discover the light room treatment industry is NOT regulated by ANY United States Government Agency. That means they are NOT subject to the same high standards you are accustomed to, and have come to expect from your vendors and product suppliers.

What’s worse, new reports are surfacing that indicate some sellers of these products may be committing consumer deception by falsely claiming their products can “disinfect,” “sterilize,” or “decontaminate,” whole rooms. In other words, it’s coming to light that the UV light theory is very deceptive to consumers. For now however, here’s something else you will probably find interesting…

THE TROUBLE WITH UV-C & PX-UV LIGHT ROOM TREATMENT SYSTEMS

Despite sleight of hand and sleight of mouth advertising claims, emerging reports are surfacing that places the UV lighting industry in peril. For example, maybe you saw a recent example of a UV-C light product failing to meet “disinfection” performance standards at the Veterans Administration (VA) here in Ohio:

“The number of C-diff rooms has increased, despite current sanitation procedures. The Louis Stokes Cleveland VA Medical Center currently utilizes the Tru-D Smart UVC part number: 036AOLF, but we are still not getting the desired results and the level of disinfection expected to especially hard to reach areas.”

Beyond that, numerous other independent peer-reviewed research papers (reported in key research journals), are showing UV room treatment systems do NOT meet the minimum Federal Government performance standards for Disinfection, Hospital Disinfection, and Decontamination.

Remarkably, the UV-C and PX-UV light room industry is not regulated by any U.S. Government Agency. Perhaps that is why (as some are saying) sellers of these products are getting away with false claims and consumer deception. It doesn’t seem to matter if the lighting system is produced by Xenex, Tru-D or another brand…they all suffer from the same laws of physics and limitations, such as:

- Diminishing power as distance increases

- Angle of exposed surfaces

- Surface shadowing

DEFINING DISINFECTION

Generally speaking, in order to claim “disinfection,” a cleaning process must attain at least a 6–Log reduction of of specific organisms in a specified period of time. Specifically speaking, both the U.S. Federal Government and the EPA state:

General Disinfection / Broad Spectrum Efficacy: a 6 Log Kill has to be obtained for both “Staph” and “Salmonella” in only 10 minutes.

Hospital Disinfection: a 6-Log Kill has to be obtained for both “Staph” and “Pseudomonas” in less than 10 minutes.

Disinfectants With Fungicidal Claims: All fungal spores at 10 and 15 minutes should be killed.

THE REPOPULATION POTENTIAL OF BACTERIA AFTER THE

FAILURE OF UV-C LIGHT AND OTHER DISINFECTING TREATMENTS

Take, for example, this report by Michelle Nerandzic, and Curtis Donskey, MD et al. “Evaluation of An Automated Ultraviolet Radiation Device For Decontamination of Clostridium Difficile and Other Healthcare-associated Pathogens in Hospital Rooms”, BioMedCentral, BMC Infectious Diseases, 2010, 10:197

C-diff spore data had a Log Reduction range of 2.2 to 3.1 for direct UV-C light exposure for 45 minutes. Per Federal standards, if a test surface is contaminated with 1,000,000 bacteria, and a Log Reduction between 2.2 to 3.1 is reached for C-diff spores, that leaves between just under 1,000 spores on the low end, to almost 10,000 on the high end.

MRSA (Staphylococcus aureus) had a Log Reduction range of 2.8 to 3.4. Per Federal standards, 1,000,000 bacteria against a Log Reduction of 2.8 to 3.4 for MRSA exposed to direct UV-C light, leaves about 100 to more than 1,000 spores left behind to repopulate.

Another research paper authored by John M. Boyce, MD, et al: “Impact of Room Location on UV-C Irradiance and UV-C Dosage and Antimicrobial Effect Delivered by a Mobile UV-C Light Device”, Infection Control & Hospital Epidemiology, June 2016, Vol. 37, NO. 6

“UV-C irradiance, UV-C dosage, and antimicrobial effect achieved in patient rooms varied significantly, depending on the location and orientation of surfaces relative to the UV-C device.”

The results of this troubling report reveals light performance was very degraded at ten (10) feet in situations where bacteria were shaded from the UV light … providing an extremely low Log Reduction of only 1.0 to 2.0 for VRE, a low Log Reduction bordering around 3.0 for MRSA, and shockingly low Log Reduction of only 0 to 1.0 for C. difficle!

Candum and Dr. Donskey et al. (2016) report a 40-minute span in the most favorable exposure orientation facing the UV-C light (sold by Tru-D and Clorox) — at only 1.22 meters away — only provided a best case Log Reduction of about 5.3 for vegetative bacteria (non- spore) MRSA (Staphylococcus aureus).

This same report reveals this lighting system could only obtain a Log Reduction of only 3.3 for C. difficle spores.

Even after 40 minutes of exposure, UV-C light treatments did not meet the Federal standards for a 6.0 Log Reduction. The manufactures claim of “disinfection” … and “no growth” claims are naturally brought into question.

GFC POLYMER PROTECTIVE SHIELD

When a virus, bacteria, or microorganism comes into contact with your new protective polymer shield, the spiked nature of the polymer shield punctures the cell membrane…and releases an energetic charge that physically ruptures the cell membrane. This duel protection is perfectly safe for humans—but ultra deadly to single-cell organisms. That’s because, in nature, most microbes carry the opposite energy charge of our polymer shield…so bacteria, viruses and germs are irresistibly drawn into contact with Germ Free Company’s polymer shield filled with spiked molecular structures. That’s because…

THE ACTION IS NOT A CHEMICAL KILL – IT’S A MECHANICAL KILL

Chemicals use poison to kill. Germ Free Company uses mechanical kill technology. As previously stated, this means relying on energetically charged particles to magnetically pull bacteria towards spiked molecular structures to continue killing bacteria around the clock.

What this really means is, there’s no killing fatigue. There’s nothing to fatigue; nothing to wear out. Unlike chemicals that evaporate, and poisons that lose potency, no energy is lost in a mechanical kill. Because there’s no evaporation, there’s no loss of potency…and because nothing is being transferred to dead cells, the antimicrobial shield doesn’t lose strength. The molecular spikes remain poised and ready for the next cell to come in contact with it.

The drawbacks, if you can call it that, is normal cleaning is necessary to prevent excess buildup of dead microbes, dirt, or other debris that may cover the spikes and prevent them from killing more microorganisms. Harsh chemicals and abrasion may, over time, dull the sharpness of the spikes, which is easily restored with a new treatment.

CONTACT US

Have an urgent need that can’t wait?

Feel free to call us directly at 440-225-2349.